建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

Antibody-drug conjugates (ADCs) represent a major advancement in drug development, delivering targeted cytotoxicity with improved clinical efficacy. An ADC consists of three key components: (1) Monoclonal antibody (mAb) – provides tumor-targeting specificity; (2) Cytotoxic payload – a highly potent cell-killing agent; (3) Linker – connects the payload to the antibody.

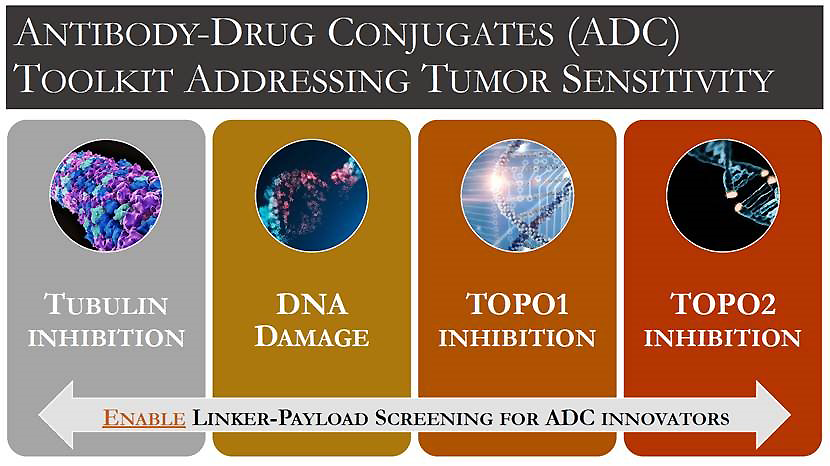

Common mechanisms of action of ADC drugs include tubulin inhibitors, DNA damaging agents, Topoisomerase 1 inhibitors, and Topoisomerase 2 inhibitors, all of which contribute to cancer cell death.

Panlabs actively develops high-value biologically synthesized products, with a strong focus on small-molecule cytotoxic drugs for antibody-drug conjugates (ADCs). Our current pipeline highlights Ansamitocin P-3 (AP3) and Calicheamicin, both naturally derived from selected microbial strains. We have completed strain engineering, fermentation optimization, and purification workflows, successfully achieving pilot-scale production exceeding 100 grams, with consistently high purity and stability. In collaboration with industry partners, Panlabs also offers a broad portfolio of commonly used ADC payloads and their derivatives, including N-Acetyl-Calicheamicin, Maytansinol (AP0), Mertansine (DM1), Belotecan, Exatecan, and Nemorubicin. In addition, we provide cleavable and non-cleavable linkers, tailored to meet diverse ADC development strategies. We welcome global partners to collaborate with us in advancing next-generation ADC therapeutics.

In addition to Ansamitocin P-3 and Calicheamicin γ1, Panlabs is actively developing a range of microbially derived products with strong market potential across antibiotics, anticancer drugs, nutritional supplements, and veterinary medicines. Our current R&D pipeline includes:

- Antibiotics: Penicillin, Cephalosporin C

- Anticancer Drugs: Doxorubicin, Staurosporine

- Antiparasitic Drugs: Milbemycin (CAS No. 1799297-76-9)

Panlabs is committed to sustainable manufacturing by integrating enzymatic catalysis into traditional chemical workflows. Enzyme-based processes operate under mild conditions, reduce the use of hazardous reagents and organic solvents, and minimize by-products and wastewater load.

Nitrilase Biocatalysis (Bio-IDA)

We developed a green biocatalytic route using nitrilase to convert IDAN into iminodiacetic acid (IDA), replacing conventional strong-acid oxidation. This approach offers mild reaction conditions, fewer impurities, simplified downstream processing, and improved safety and environmental performance.

Catalase Engineering for Wastewater Treatment

Panlabs also engineered catalase with enhanced activity and stability under high H₂O₂ concentrations, metal ions, and a wider range of pH temperature. This enzyme is suitable for semiconductor wastewater treatment, enabling rapid hydrogen peroxide decomposition, reduced chemical consumption, and improved operational safety and sustainability.

Through enzyme engineering, Panlabs provides efficient, low-risk, and environmentally friendly green process solutions for diverse industries.