建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

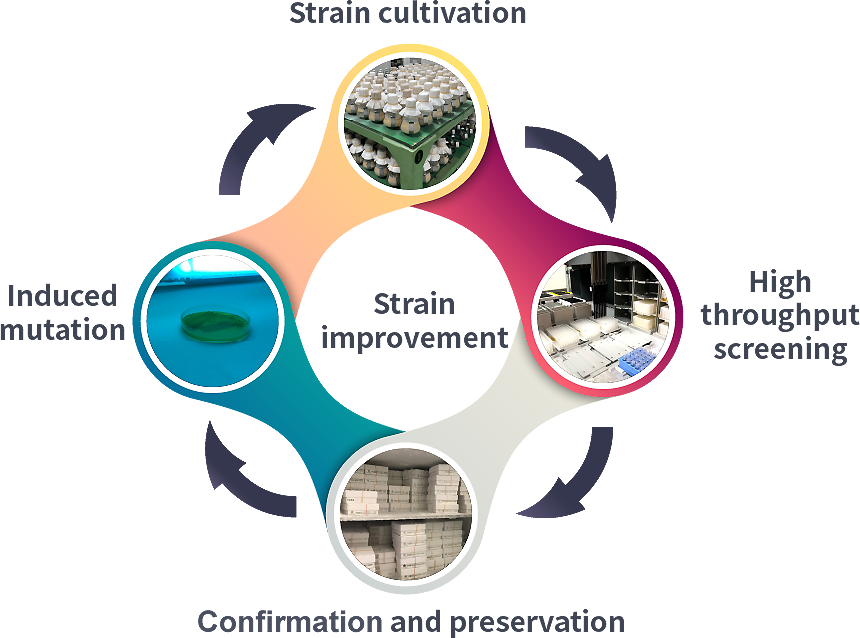

Strain Improvement

With over 50 years of experience in industrial microbial strain and enzyme improvement, Panlabs is highly skilled in operating various aerobic and anaerobic microorganisms. By employing professional, customized techniques combined with media optimization, we significantly increase the industrial production value of strains.In addition to large-scale shaker fermentation selection equipment, Panlabs has integrated micro-fermentation equipment and automated systems to accelerate strain screening, improve throughput and screening efficiency, and provide our customers with the highest quality strain solutions.

Enzyme Improvement and Products

Panlabs applies molecular biotechnology and protein engineering to develop highly efficient enzymes with enhanced catalytic performance. These enzymes operate under mild reaction conditions, reducing energy consumption and waste generationideal for green manufacturing and aligned with our customers' sustainability goals. Panlabs offers a diverse portfolio of enzymes for industrial and bioprocessing applications, including:

- Enzymes: Amylase, Lipase, Nitrilase, Endonuclease, Glucose Oxidase

- Proteases: SUMO protease, TEV protease

Global Microbial Strain Library

Panlabs is a leading microbial development company with a comprehensive strain library of over 20,000 fungal and actinomycete strains sourced from diverse geographical and ecological environments worldwide. We provide high-value natural products and microbial-based solutions with broad applications in pharmaceuticals, agriculture, functional foods, cosmetics, and environmental sustainability. Our strain library is not subject to the Nagoya Protocol, allowing unrestricted access for the discovery of novel bioactive natural compounds. If you are interested in exploring our microbial strain resources, please feel free to contact us!

Microbial Strain Licensing

We have curated a portfolio of representative microbial strains capable of producing key natural compounds, with applications in drug development, immunology research, veterinary and pet health, agricultural biocontrol, and biotechnology.

These strains and their production processes are available for licensing and technical collaboration, supported by comprehensive research data and detailed fermentation protocols. We sincerely invite interested partners to collaborate with us in advancing innovative applications and driving industrial development.

| No. | Product | Strain | Properties / Mechanism | Application |

| 1 | Doxorubicin | Streptomyces sp. |

|

|

| 2 | Staurosporine/Midostaurin | Streptomyces sp. |

|

|

| 3 | Calicheamicin | Micromonospora sp. |

|

|

| 4 | Tacrolimus | Streptomyces sp. |

|

|

| 5 | Milbemycin | Streptomyces sp. |

|

|

| 6 | Spinosad | Saccharopolyspora sp. |

|

|

| 7 | Paraherquamide | Penicillium sp. |

|

|

(Terpenoid/Polyketide Derivative, Fungi)

(Cyclic Polypeptide, G(-) Bacteria)

Hit rate:

Antibiotic resistance selection (ribosome engineering): 43% (3/7)

Random selection: 5.8% (4/69)

Combing heterologous gene expression with molecular and classical yield improvement, we optimized lactoferrin production.

For our client Agennix, Inc. (Houston, TX, USA) (Bio/Technology, 1995,13:498-503)