建議您使用以下瀏覽器觀看本網站,

以獲得最佳瀏覽效果。

Antibody-drug conjugates (ADCs) represent a major advancement in drug development, delivering targeted cytotoxicity with improved clinical efficacy. An ADC consists of three key components: (1) Monoclonal antibody (mAb) – provides tumor-targeting specificity; (2) Cytotoxic payload – a highly potent cell-killing agent; (3) Linker – connects the payload to the antibody.

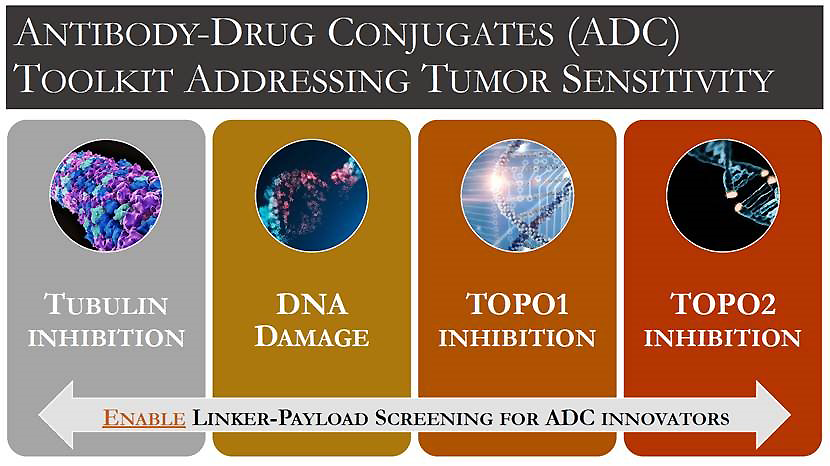

Common mechanisms of action of ADC drugs include tubulin inhibitors, DNA damaging agents, Topoisomerase 1 inhibitors, and Topoisomerase 2 inhibitors, all of which contribute to cancer cell death.

Panlabs actively develops high-value biologically synthesized products, with a strong focus on small-molecule cytotoxic drugs for antibody-drug conjugates (ADCs). Our current pipeline highlights Ansamitocin P-3 (AP3) and Calicheamicin, both naturally derived from selected microbial strains. We have completed strain engineering, fermentation optimization, and purification workflows, successfully achieving pilot-scale production exceeding 100 grams, with consistently high purity and stability. In collaboration with industry partners, Panlabs also offers a broad portfolio of commonly used ADC payloads and their derivatives, including N-Acetyl-Calicheamicin, Maytansinol (AP0), Mertansine (DM1), Belotecan, Exatecan, and Nemorubicin. In addition, we provide cleavable and non-cleavable linkers, tailored to meet diverse ADC development strategies. We welcome global partners to collaborate with us in advancing next-generation ADC therapeutics.

In addition to Ansamitocin P-3 and Calicheamicin γ1, Panlabs is actively developing a range of microbially derived products with strong market potential across antibiotics, anticancer drugs, nutritional supplements, and veterinary medicines. Our current R&D pipeline includes:

- Antibiotics: Penicillin, Cephalosporin C

- Anticancer Drugs: Doxorubicin, Staurosporine (a precursor to Midostaurin)

- Antiparasitic Drugs: MLB (CAS No. 1799297-76-9)

In response to global sustainability trends, Panlabs is also investing in mycoprotein (fungal protein) development. By screening high-performing fungal strains from our proprietary library, we aim to create alternative non-animal proteins suitable for plant-based meats and animal feed applications, supporting both carbon reduction and circular economy goals. Compared to traditional livestock farming, fungal protein production is faster, more resource-efficient, and scalable, making it a key enabler of net-zero carbon biotechnology. We welcome partnerships with sustainability-driven enterprises to co-develop the next generation of green biomanufacturing solutions.

Contact Panlabs to request samples and explore collaboration opportunities.